The dynaROCK II works according to the Leeb rebound hardness test me-thod for metallic materials. It is developed and produced by BAQ GmbH. The dynaROCK II combines easy operation with high precision and reliability. For different applications, six impact device types are available. The type of the connected impact device is identified automatically.

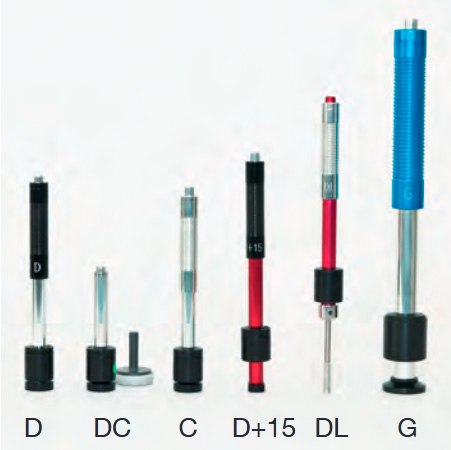

Type D :

Standard impact device for most hardness testing tasks

Type DC :

Extremely short impact device for measurements at difficult-to-access locations or in pipes

Type C :

Impact device with reduced impact energy e.g. for measurements on surface-hardened parts

Type D+15 :

Impact device with small placement surface

Type DL :

Impact device with longer impact body

Type G :

Impact device with increased impact energy for measurements on heavy casting and forged parts. The surface quality requirements are lower as with type D. Measurement range up to Brinell 650 HB

Scope of delivery :

Basic device, impact device type D with cable, hardness comparison block with manufacturer‘s calibration, cleaning brush, manual, interface cable, USB charging adapter, PC software, case

Optional accessories :

placement rings for measurements on curved surfaces (concave / convex), hardness comparison blocks with calibration certificate for impact devices Dxx and C in 3 different hardnesses, hardness comparison blocks with ca-libration certificate for impact device G in 2 different hardnesses