Products

- Home

- Products

- Advance NDT Products

- Phased Array and Tofd Scanner

- Scanner and Encoder

Phased Array and Tofd ScannerBack

Scanner and Encoder

Encoder With Connector for Standard PA Unit and compatible for Scanner

Industrial Scanner - for

Corrosion Detection,

Weld Detection

Composite Material Detection

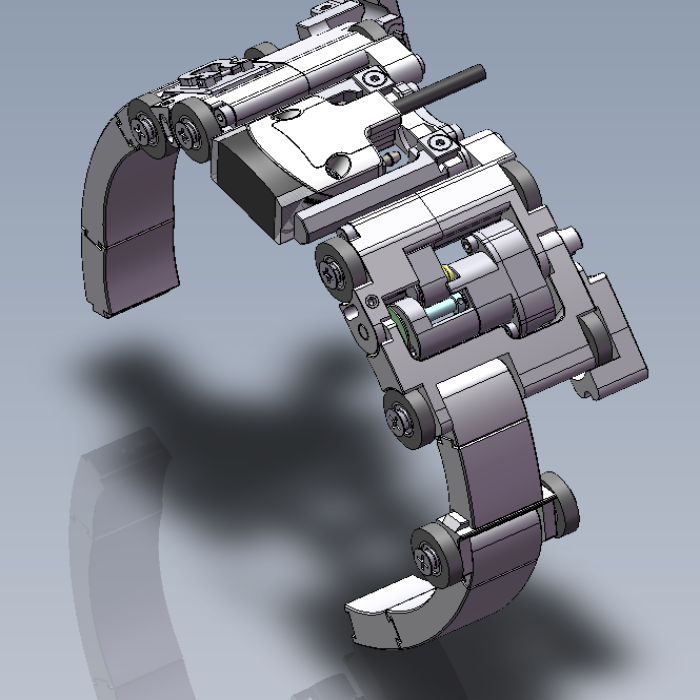

Roller Scanner ( Wheel Scanner ) - For Detecting Composite And Other Smooth Surface material ., Such as Carbon Fiber and Other Composite materials commonly used in - Aerospace Industry. The Wheel Scanner also provides a feasible alternative liquid Immersion detection technology. Roller scanner R1, its ergonomic design makes it the perfect tool for manual scanning. Encoder with various connector is available on request, support Olympus, M2M, GE, ZETEC, etc

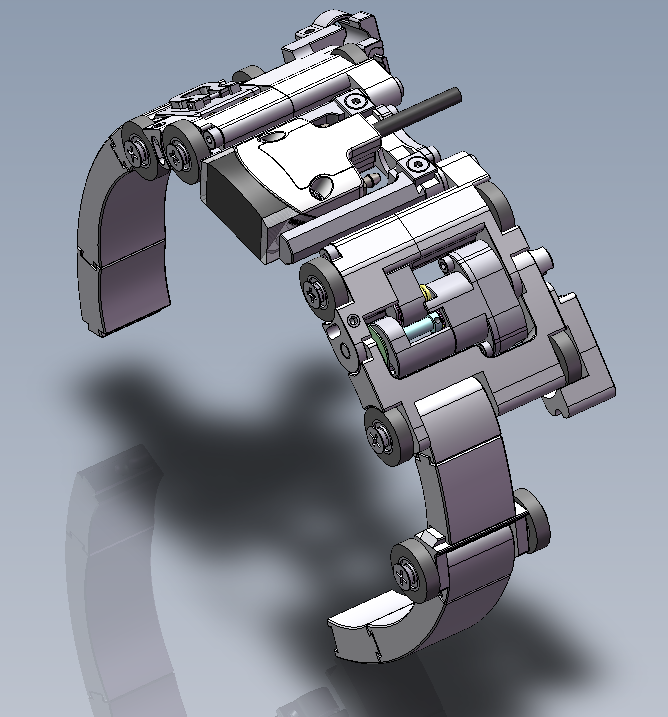

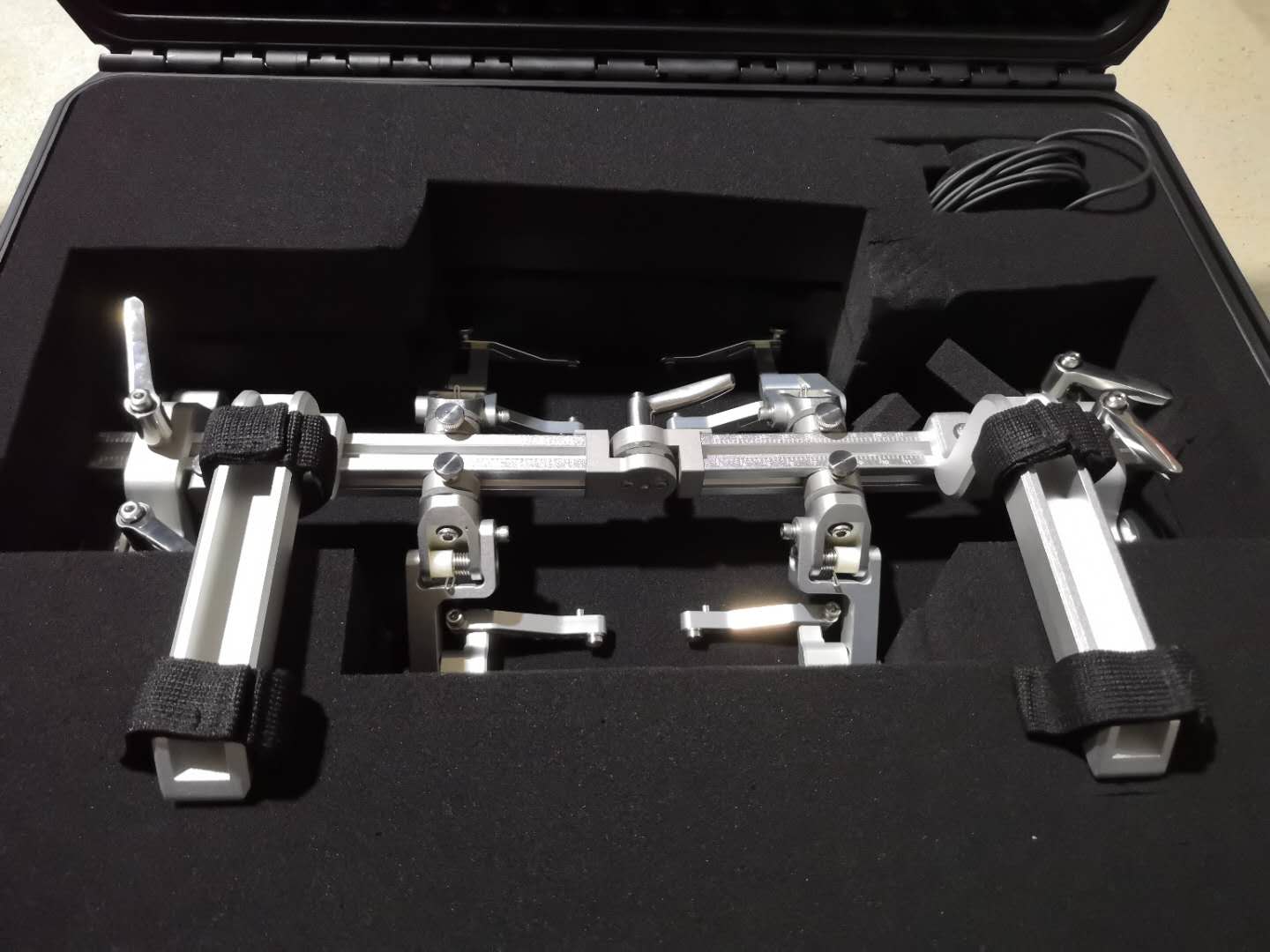

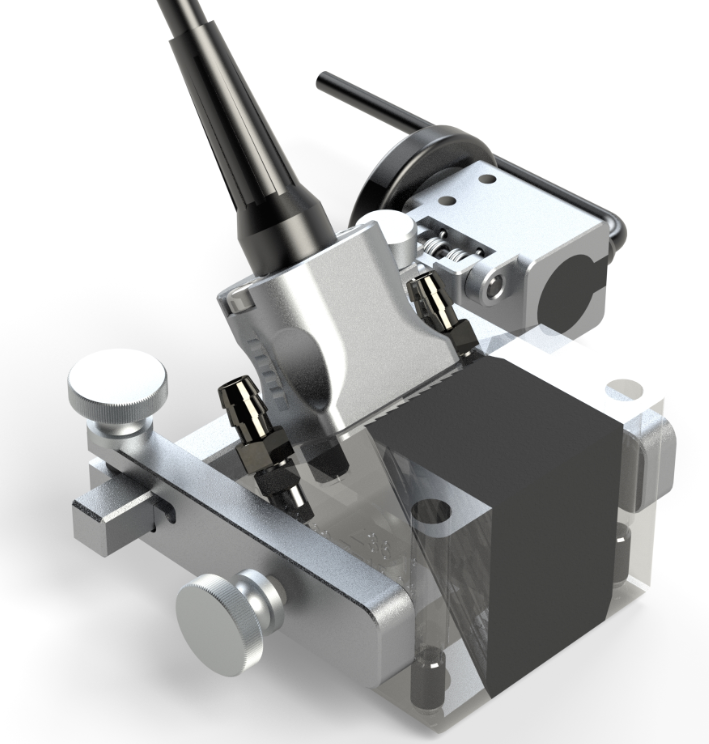

R3 Scanner - Weld Scanner -

Is a general pipe and plate scanner which can detect longitudinal and annular welds by angle adjustment. The scanner can install one or two pairs of probes and can detect welds by using the TOFD (Time Of Flight Diffraction) probe, PA (Phased Array) probe, and pulse-echo technology at the same time. R3 Scanner adopts standard modular design and can be freely combined into double rod or single rod. The basic modules are as follows: Single rob module, Double rob module, Clamping holder A module, Clamping holder B module, Handle module, Magnetic wheel module, Encoder module.

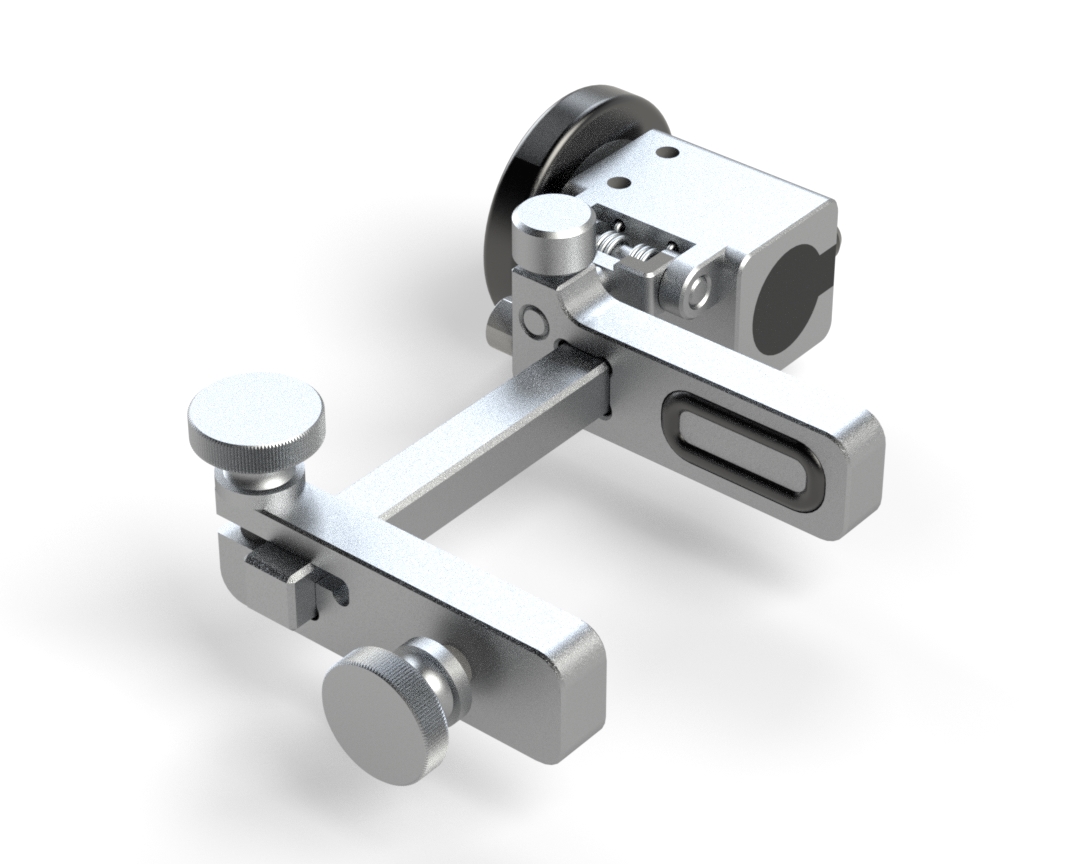

Micro scanner R6,

its small and ergonomic design makes it the perfect tool for manual scanning in restricted space limitation areas. Enhance corrosion scanning with versatility, functionality, and simplicity. Encoder with various connector is available on request, support Olympus, M2M, GE, ZETEC, etc

| Model | Features and Applications |

| R3-D | 1. PA-TOFD weld scanner can be used for phased array and TOFD |

| Double rob model | inspection of flat butt welds and pipe circumferential welds |

| 2. Support up to 4 probes and can remove clamping arm manually | |

| 3. Support encoder scanning, quick disassembly, and easy installation | |

| 4. The spacing of the walking wheels can be adjusted, work freely in small | |

| detection space. | |

| 5. Excellent adaption, can hold wedges in different sizes | |

| R3-S | 1. PA-TOFD weld scanner can be used for phased array and TOFD |

| Single rob model | inspection of flat butt welds and pipe circumferential welds |

| 2. Support up to 2 probes and can remove clamping arm manually in | |

| aside | |

| 3. Support encoder scanning, quick disassembly, and easy | |

| installation | |

| 4. The spacing of the walking wheels can be adjusted, work freely in | |

| small detection space. | |

| 5. Excellent adaption, can hold wedges in different sizes | |

| .Technical specification | |

| Double rob assembly dimension | |

| Length (mm) - 184mm Width (mm) - 450mm Height (mm) - 111mm | |

| Single rob assembly dimension | |

| Length (mm) - 184mm Width (mm) - 350mm Height (mm) - 111mm | |

| Double rob assembly package | |

| Net weight (kg) - 2.40Kgs | Gross weight (kg) - 8.90Kgs || Package box (mm) - 570x235x465mm | |

| Single rob assembly package | |

| Net weight (kg) - 1.65Kgs | Gross weight (kg) - 8.20Kgs || Package box (mm) - 570x235x465mm | |

| Scanner R6 | 1. single probe simple scanner is mainly used for single phase array controlled probe recordable detection of pipeline and flat weld |

| 2. simple structure, quick disassembly, and convenient installation | |

| 3. Be able to assemble encoder for scanning, and change the clamping direction of encoder 90 ° as required, compatible with "Axial scanning" and "Circumferential scanning" | |

| 4. the clamping width is adjustable, and the maximum clamping width is 58mm. It can also be customized to increase the clamping width | |

| 5. Support encoder scanning, quick disassembly, and easy installation | |

| Flexible probe scanner | 1. Bent to fit the workpiece surface at axis direction 3-4mm thick, can be |

| placed inside the pipe for inner inspection | |

| 2. Pipeline and bar corrosion inspection, Can be used for different | |

| diameters | |

| 3. Other complex geometric artifacts | |

| 4. The workpiece can be measured and imaged | |

| 5. Simple structure, quick disassembly, and convenient installation | |

| 6. Support encoder scanning, quick disassembly, and easy installation | |

| Encoder E01 | 1. Stainless steel silent bearing structure, durable and stable. |

| 2. Epoxy wear-resistant Pu rubber coated roller, no wear of workpiece. | |

| 3. Cable Connection Top or side. | |

| 4. Precision step (12 steps / mm) resolution scale. | |

| 5. The encoder pin shaft (3mm) is locked with screws. | |

| 6. Easy to realize 90-degree angle scanning with conversion axis. | |

| 7. The coding wheel with elastic support of double torsion spring can be | |

| pressed reliably, adapt to a complex environment, and detect accurately | |

| R1 Roller Scanner | 1. High coupling effect with minimal couplant |

| 2. Easy setup and have efficient C-scan | |

| 3. 25mm(0.98 in) water delay block for 50 mm (1.97in) composites | |

| inspection. | |

| 4. Up to 51.2 mm wide beam coverage | |

| 5. Low transparent wheel material | |

| 6. Zero-degree detection of composite materials and other | |

| materials with a smooth surface. | |

| 7. Plates corrosion detection, axial corrosion detection in large-diameter pipes. | |

| .Specifications of Roller wheel scanner | |

| 1. Typical near surface resolution (reflector with a flat diameter of 3 mm) | |

| 2. 1 mm, 5 MHz (composite); 1.5mm, 3.5MHz (composite); 3mm 5MHz (steel / aluminum) | |

| 3. Minimum surface curvature (convex radius) - 50mm | |

| 4. Location of secondary interface echo (in composites) - 50 mm | |

| 5. Encoder voltage - 5 V | |

| 6. Weight (w/o liquid) 1.7KG | |